Established in 1973, NCS Engineering was one of the first companies in South Africa with CNC machines, servicing the mining and motor industries. In the early eighties while working with the mining industry, we identified a need for failsafe brakes for mining vehicles. Hence the MaximB braking system was developed, one of the first wet failsafe braking systems.

This patented system was developed in order to solve safety issues faced by the mines.

The underground trackless mining vehicles being the target for these products. These products have since evolved dramatically and are now also aimed at other surface vehicles and for numerous applications. The braking systems have since proven to be reliable systems requiring minimal maintenance.

The brakes are price and quality competitive. The success of the earlier 500 and 300 series braking systems resulted in the expansion of the product offering to the market, with our most popular brake the 200 series for the Landrover and other similar vehicles.

We also have braking systems for towed trailers, commercial vehicles and LDV’s, Tractors and some specialized developments and conversions.

- Front and Rear Fail Safe (FS) braking systems.

- Front and rear closed service brakes.

The company has been an ISO9001 certified company since the early 90’s, currently certified as ISO9001-2008 compliant. NCS strives to provide superior products with the highest safety standards, exceptional service, and unmatched quality at a cost-effective price.

How our MaximB

braking system works

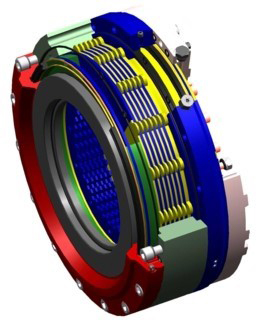

MaximB failsafe brakes are Spring Applied Failsafe, Hydraulic Applied Service Brakes (SAFHAS). Both braking mechanisms are enclosed in the same housing and are sealed and liquid cooled, working on the scientific principal of oil shear between the rotating and stationary components. The unit has separate service and failsafe systems providing a very robust and safe solution for brakes used in mining.

The brake operates in two ways:

Service braking:

- The service brake is applied by exerting pressure using the standard foot brake valve.

Failsafe braking:

- The Emergency Stop button is pressed.

- The engine stalls.

- The engine is switched off.

- The door switch or seatbelt switch (additional safety features) is pressed.

Benefits of the MaximB

failsafe braking system

| Feature | MaximB | Competitor A | Competitor B |

|---|---|---|---|

| Test certification on manufacture & repair | ✓ | ✗ | ✗ |

| Axle modification | ✗ | ✓ | ✓ |

| Monthly high priced lubricant change | ✗ | ✓ | ✓ |

| Enclosed | ✓ | ✓ | ✗ |

| 1 day installation | ✓ | ✗ | ✗ |

| SANS: 1589:2012 | ✓ | ✗ | ✗ |

Proven Safety

- The failsafe system ensures that the vehicle cannot roll away unexpectedly.

- New brake derivatives are tested and assembled in house.

- All brakes undergo static testing and dynamic testing, using a specially designed dyno meter ensuring each break meets required design standards as well as SANS: 1589:2012.

- All refurbished brakes undergo the same rigorous testing and are then issued with a test certificate. The brake serial number tracking ensures that we can monitor and track brake lifecycles, further assisting customers with their cost analysis. Any abnormal wear is highlighted and a complete vehicle and condition survey can be recommended to ensure that the system is offering optimal value.

- The MaximB brand is alone in the rigorous testing procedures it applies, resulting in complete customer peace of mind.